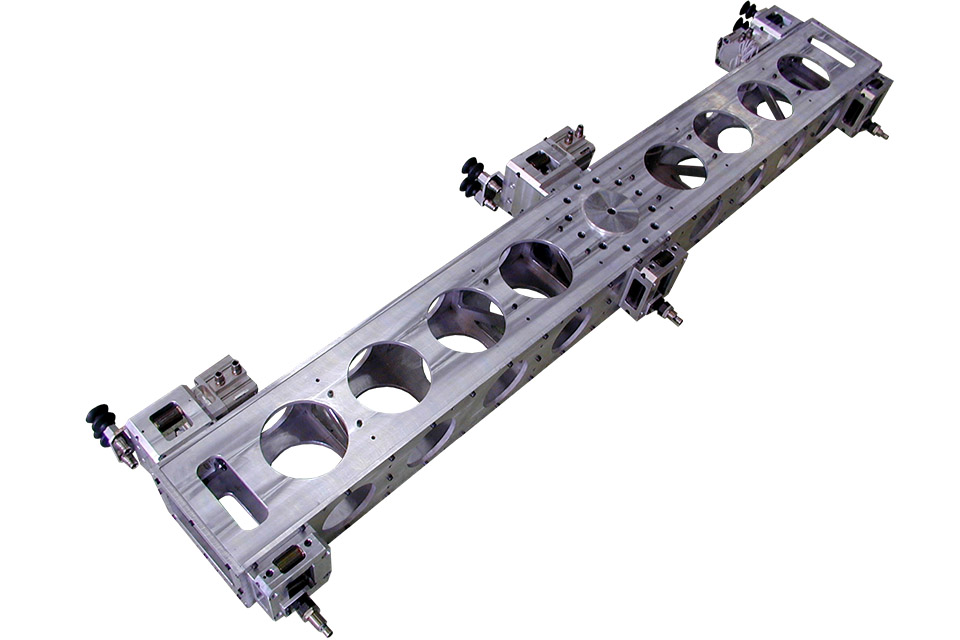

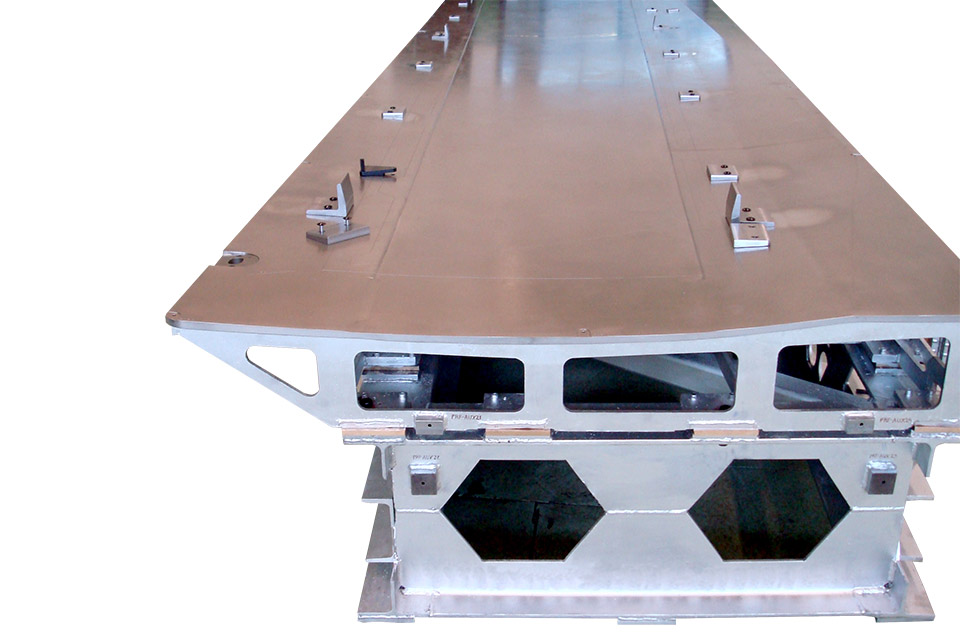

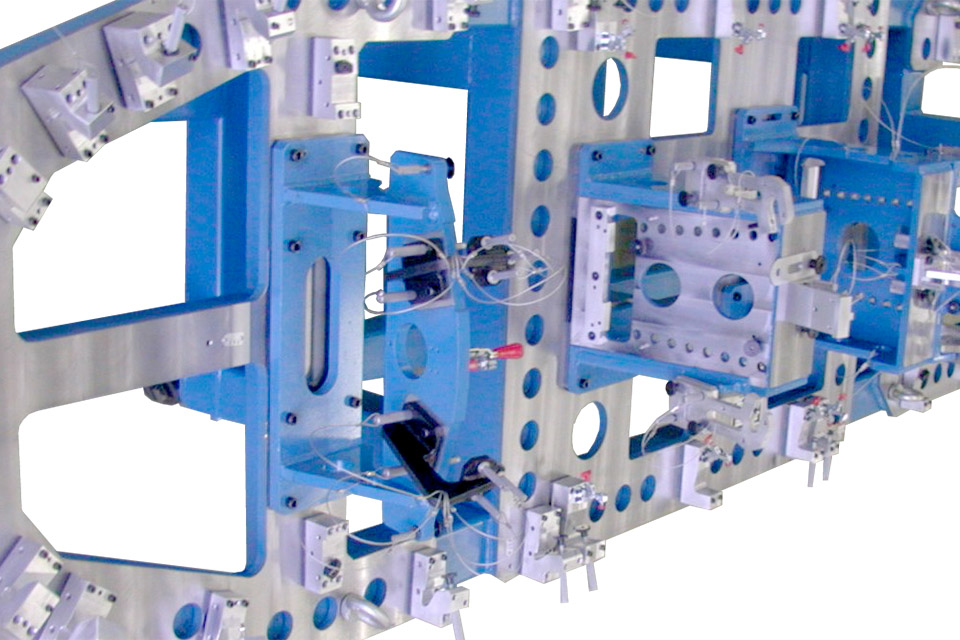

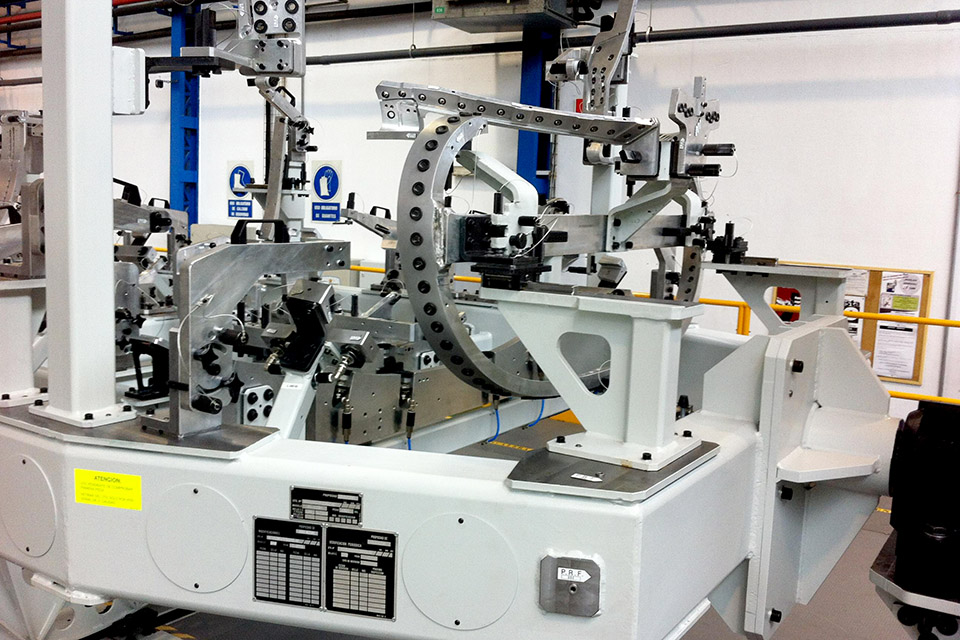

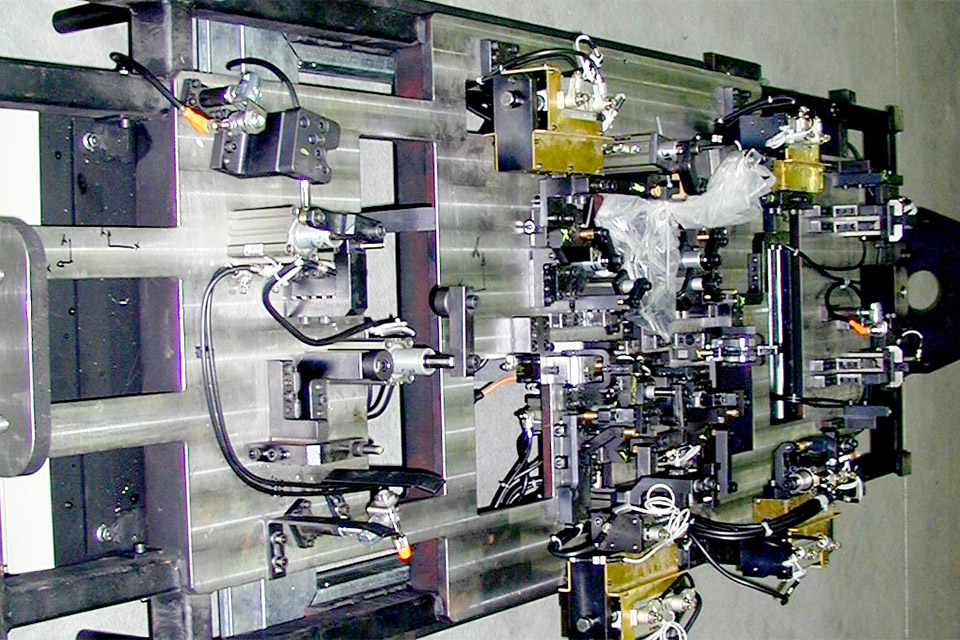

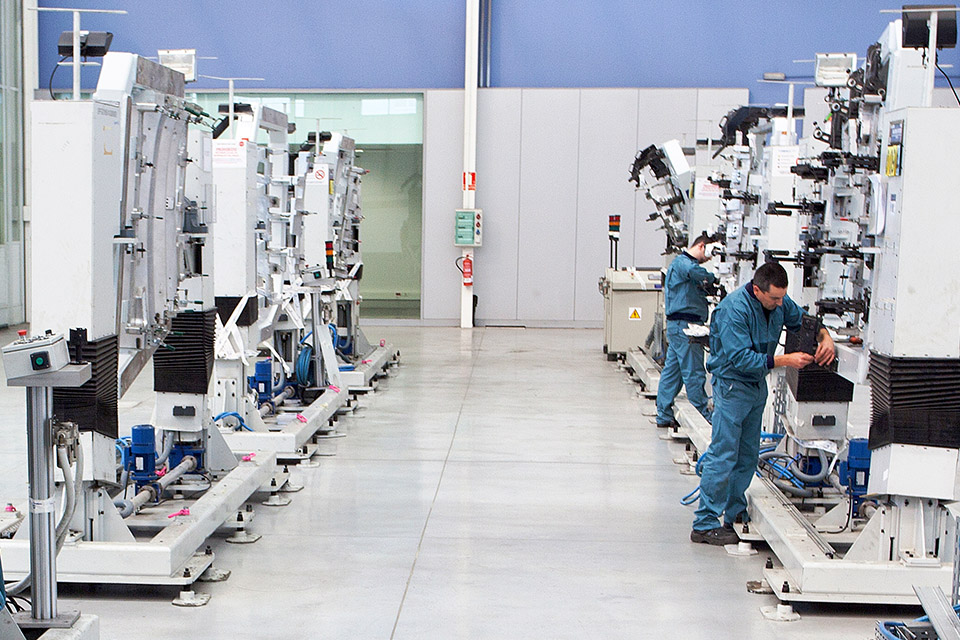

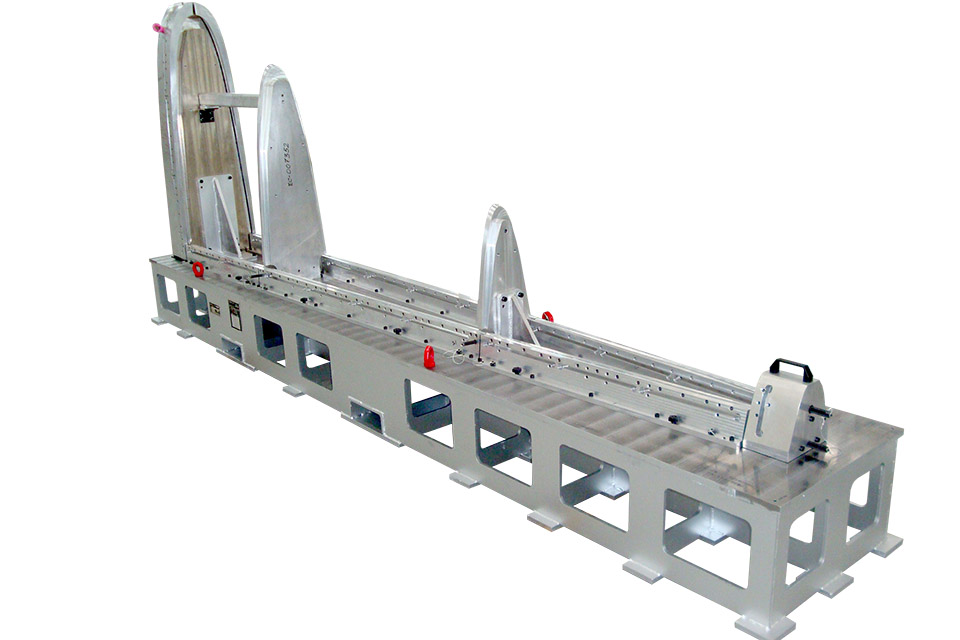

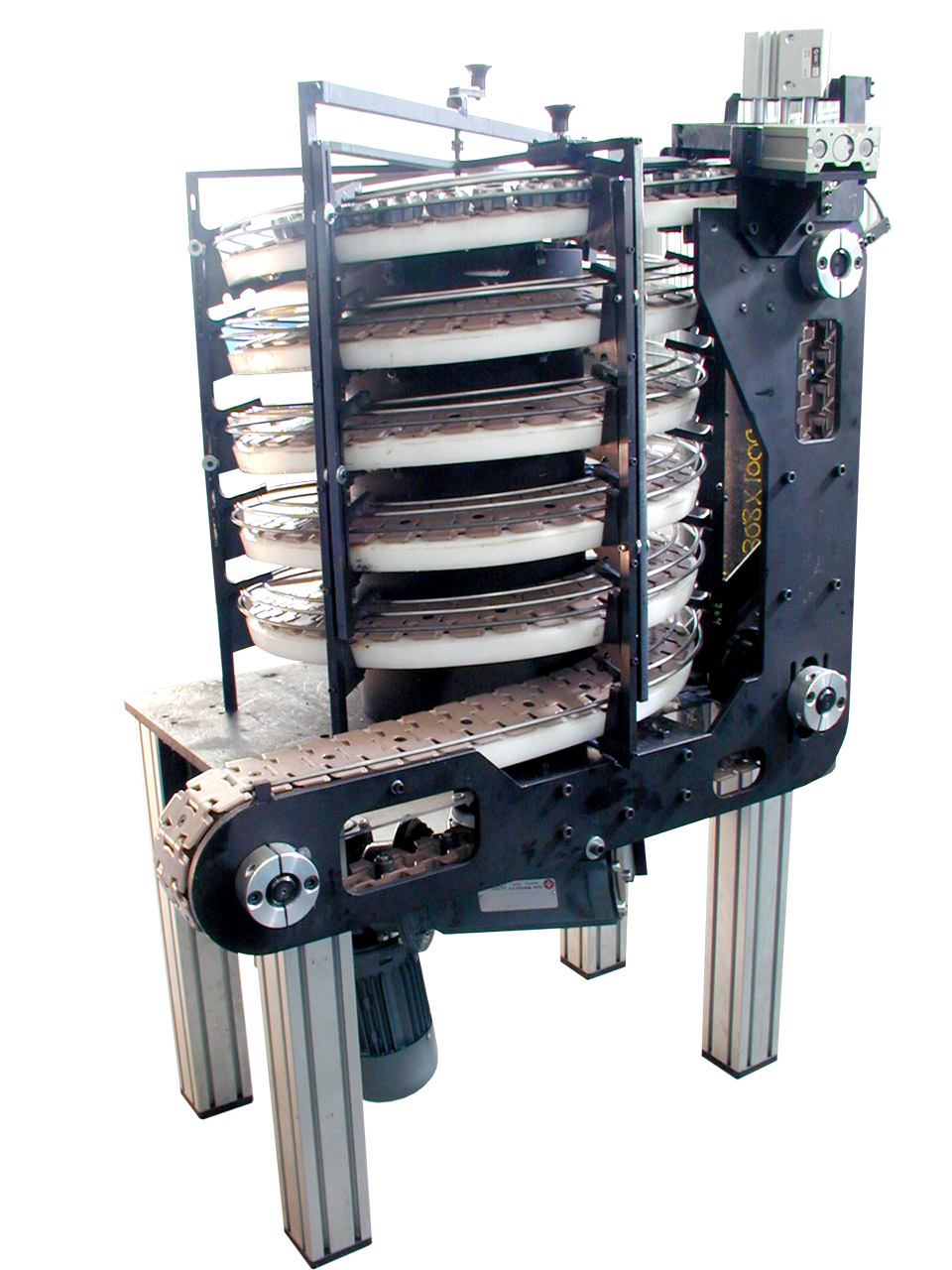

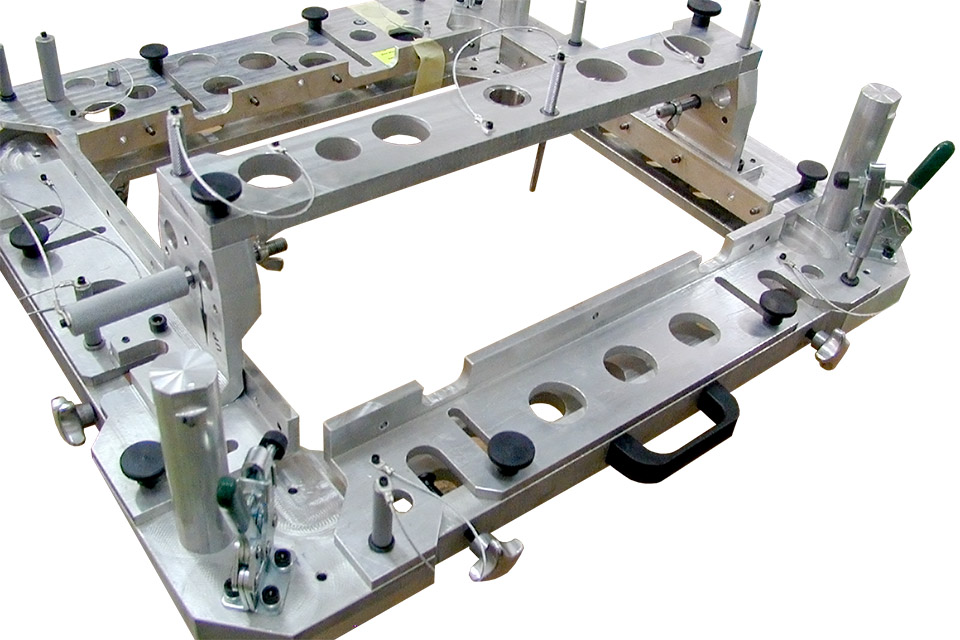

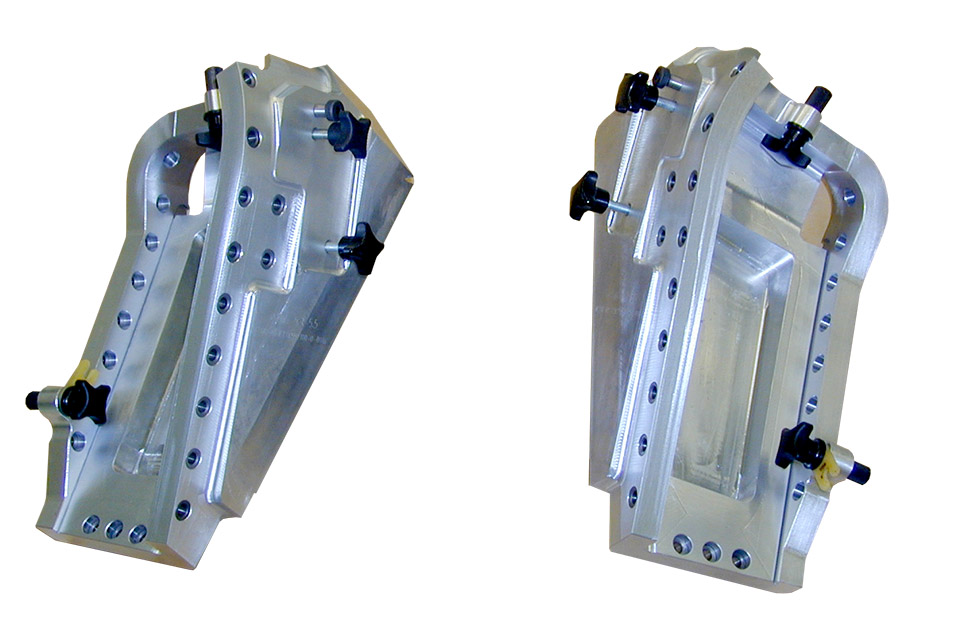

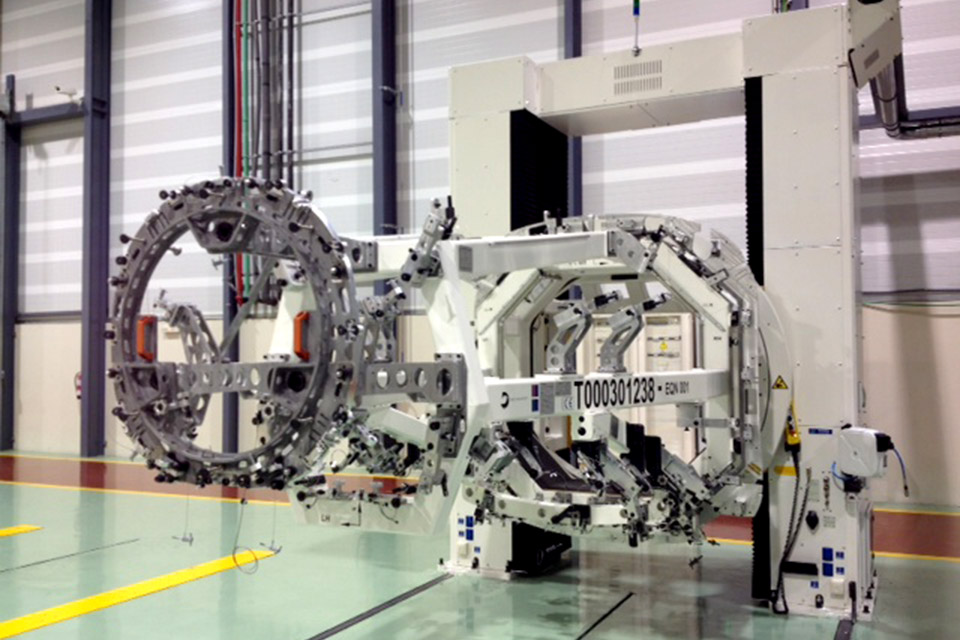

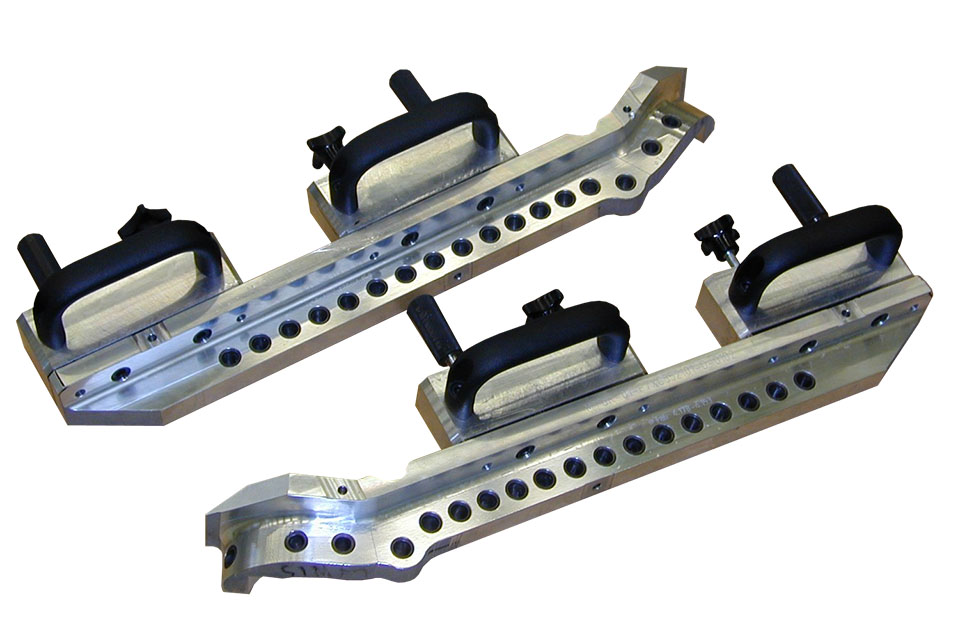

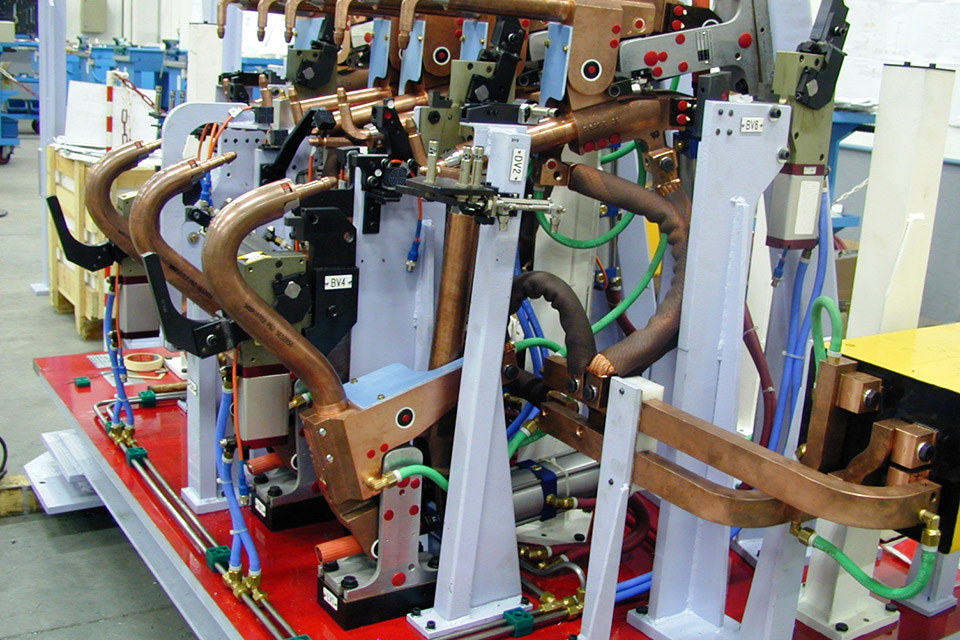

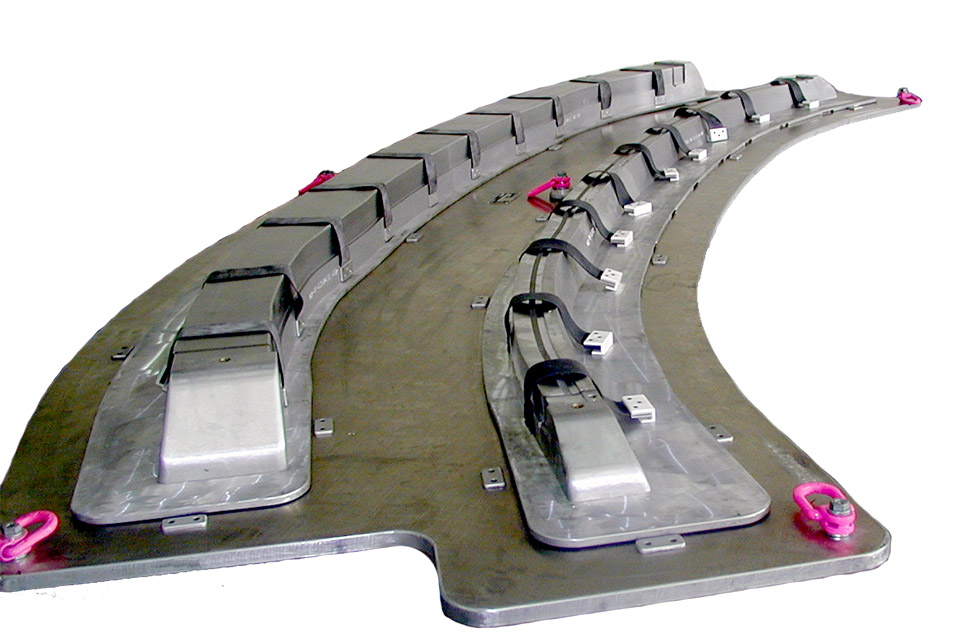

We have extensive experience in the development of turnkey projects related to the design and the manufacture of tools and assembly jigs.

These include the entire process: project study and lay-out design, development of specific tools and operations automation.

All the tools and capital equipment are manufactured in-house, being Delta Group responsible for:

Design concept

2D and 3D design (CATIA – all versions)

Calculation of finite elements (CATIA)

Mechanical welding and metal forming

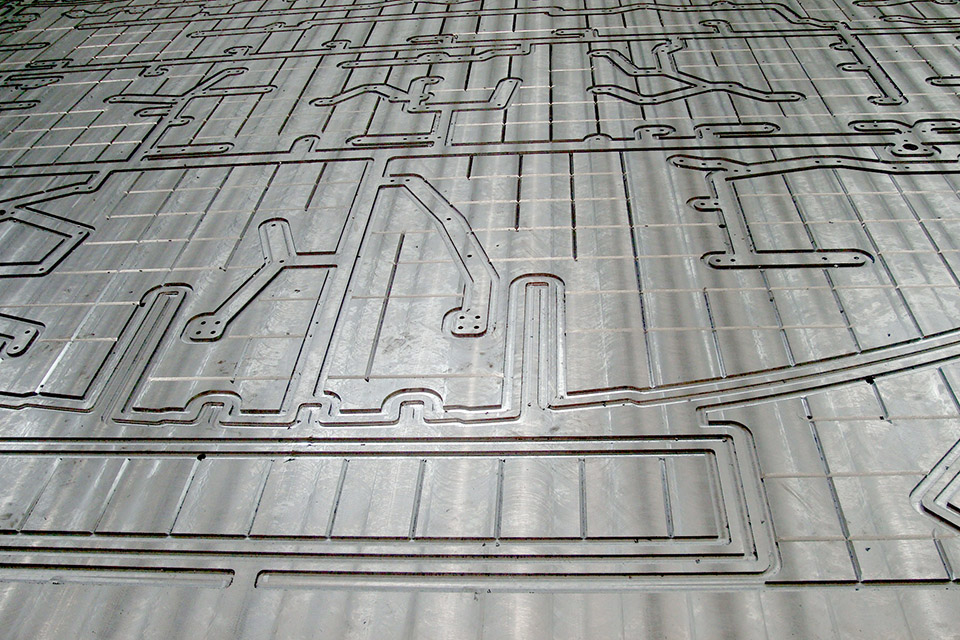

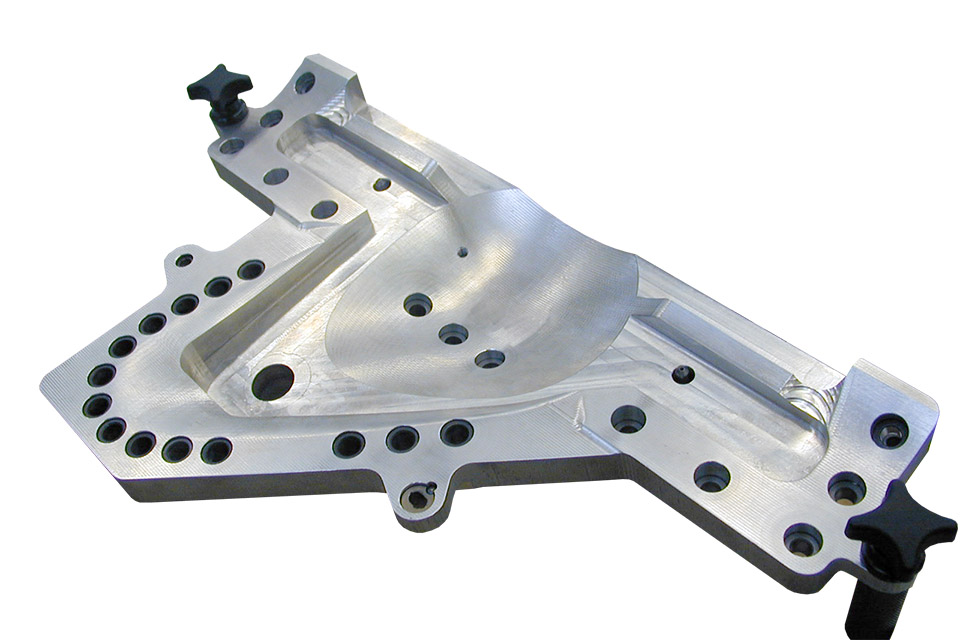

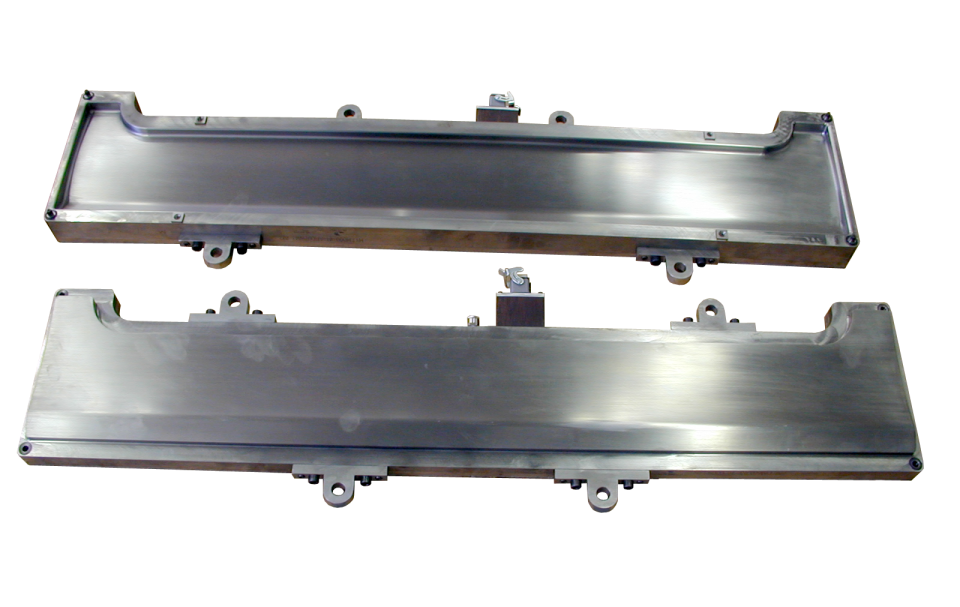

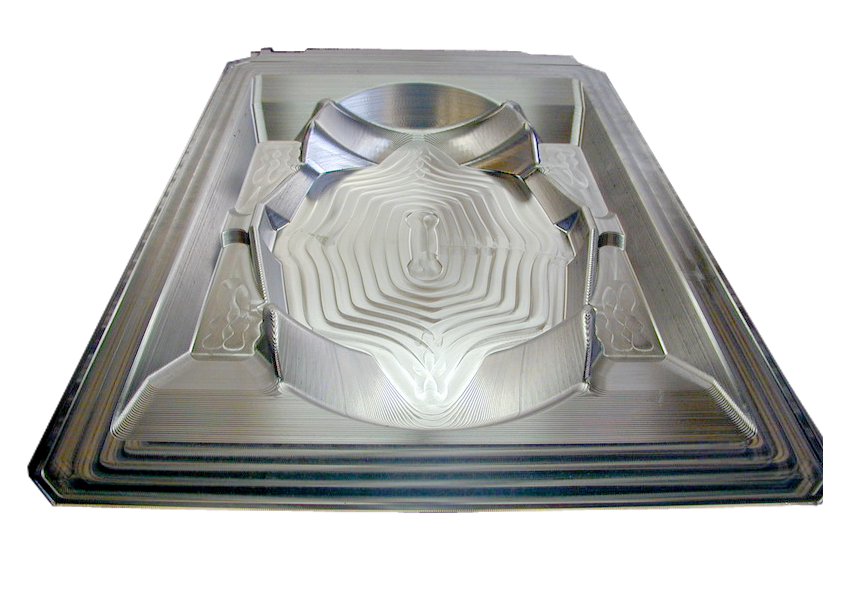

CNC (CATIA, TEBIS)

Machining on 5 axis up to 24 meters: lathes, milling machines, wire and die-sinking EDM, grinding machines,…

Thermal treatments

Stress relief

Superficial treatments

Air tightness tests: helium, vacuum bag, penetrating liquids,…

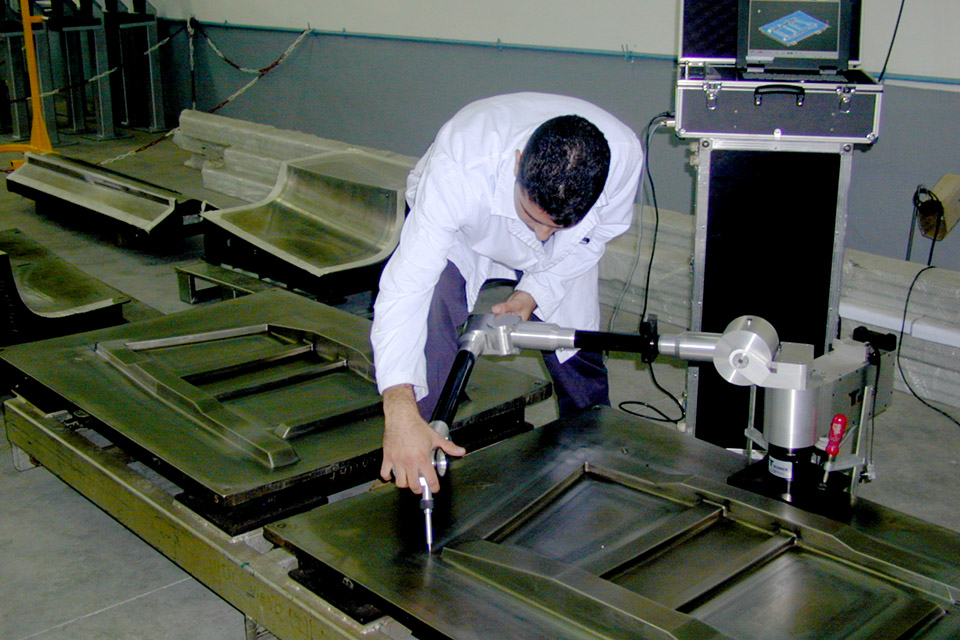

Metrology: 4 CMM’s (up to 12m), 2 Rommer, 3 Laser-Tracker and 3 headed scanner for CNC Machines with 3D measurement, with digitalization software (Reverse engineering)

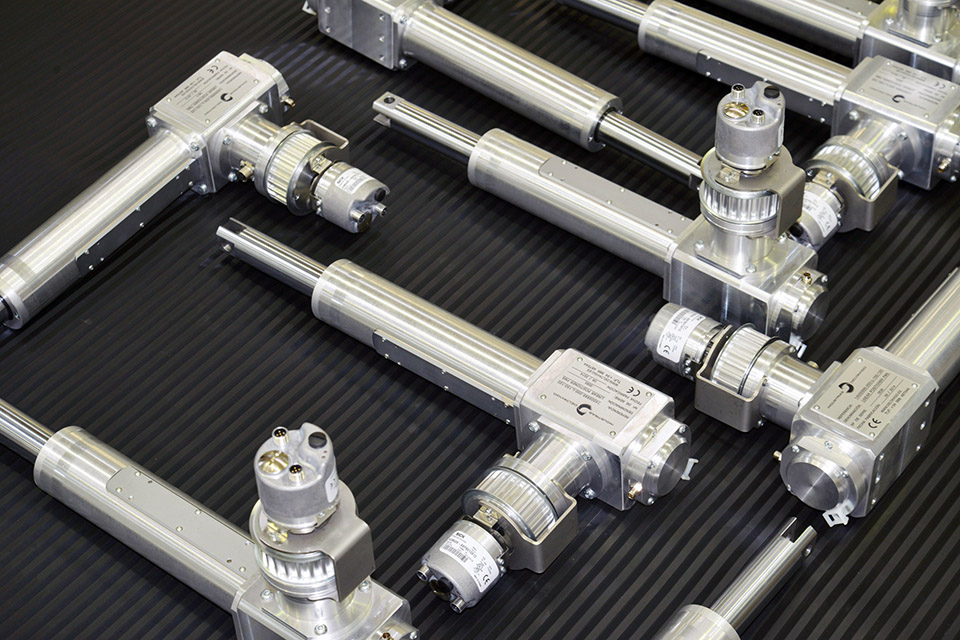

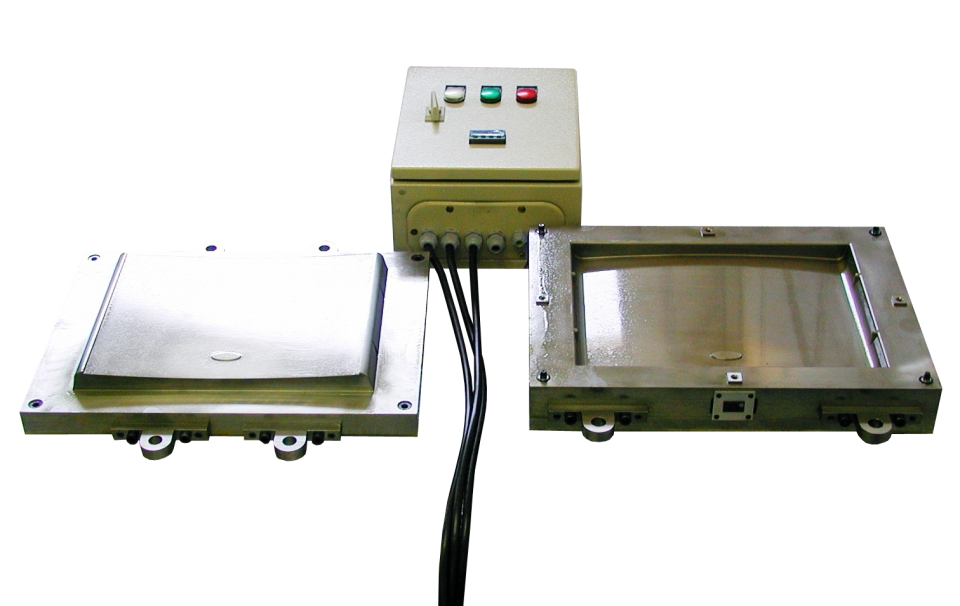

Electrical installations (XELEC)

Pneumatics (XFLUID)

Hydraulics

Set-up

Commissioning

CE certification

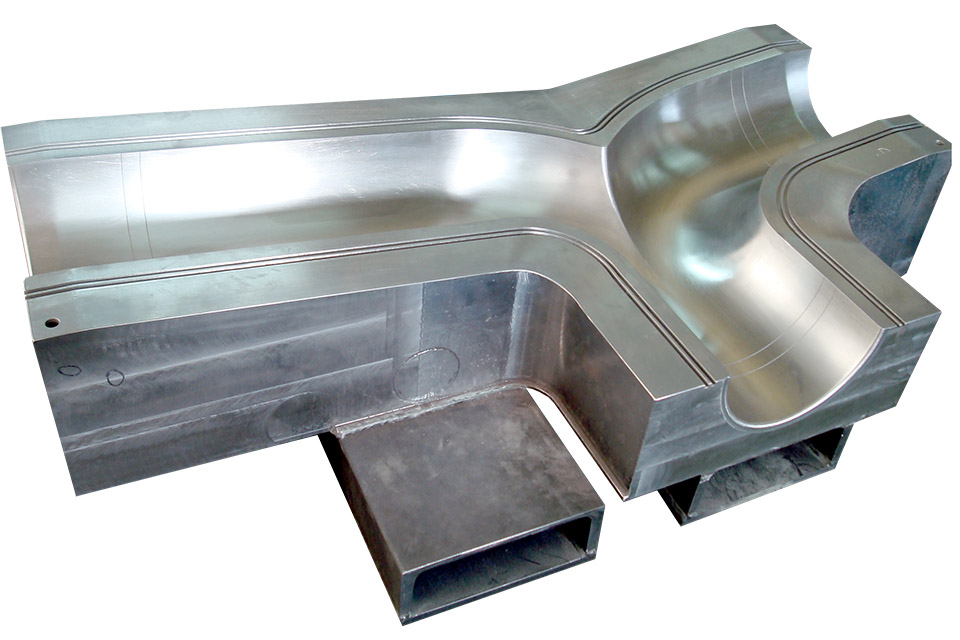

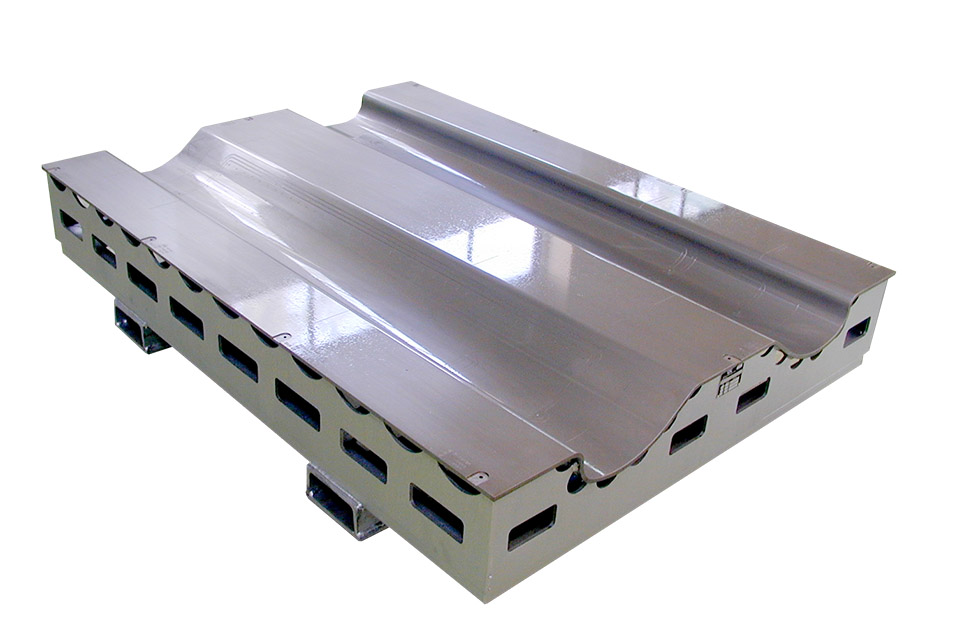

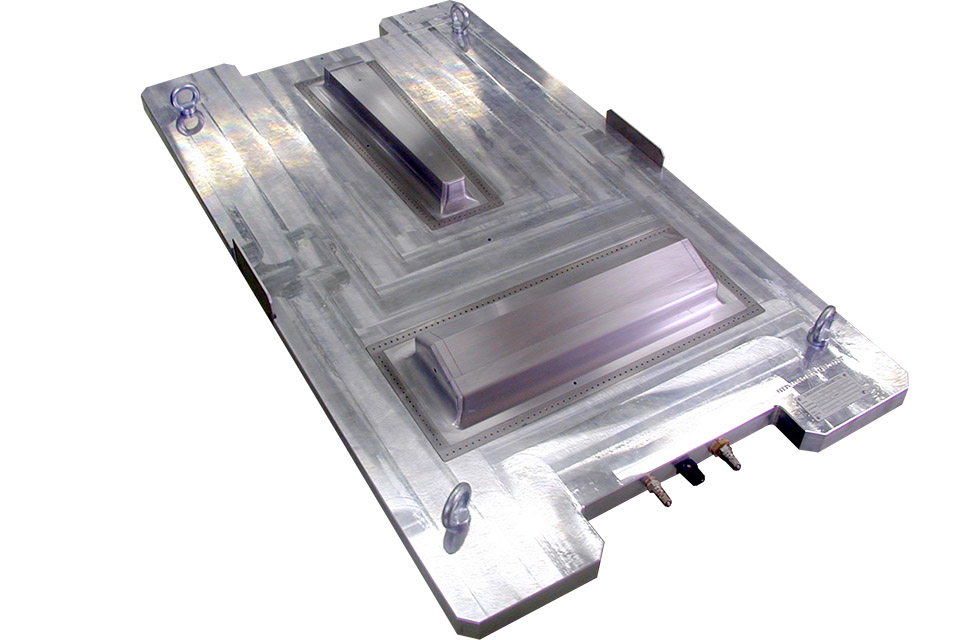

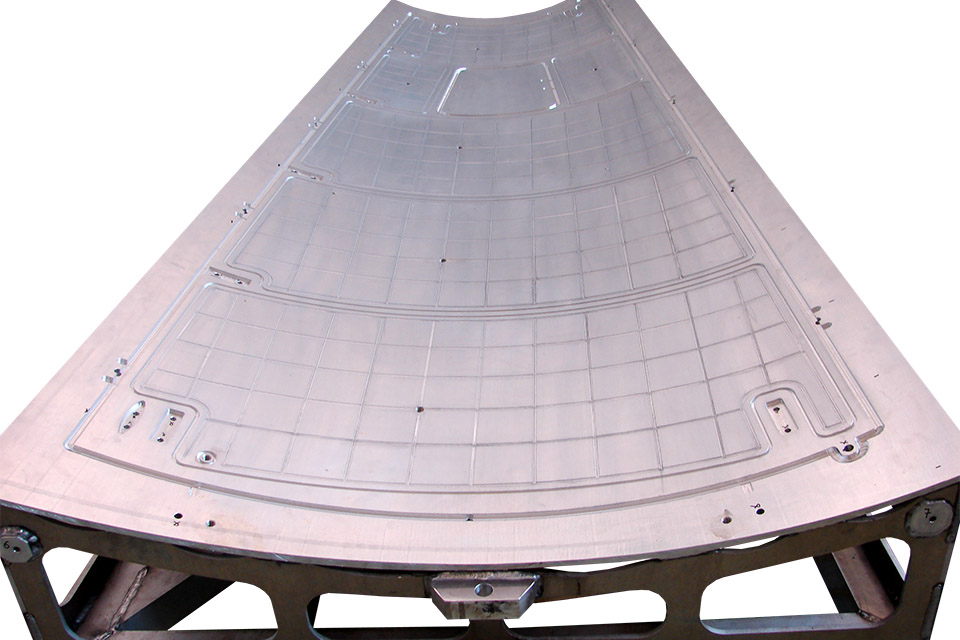

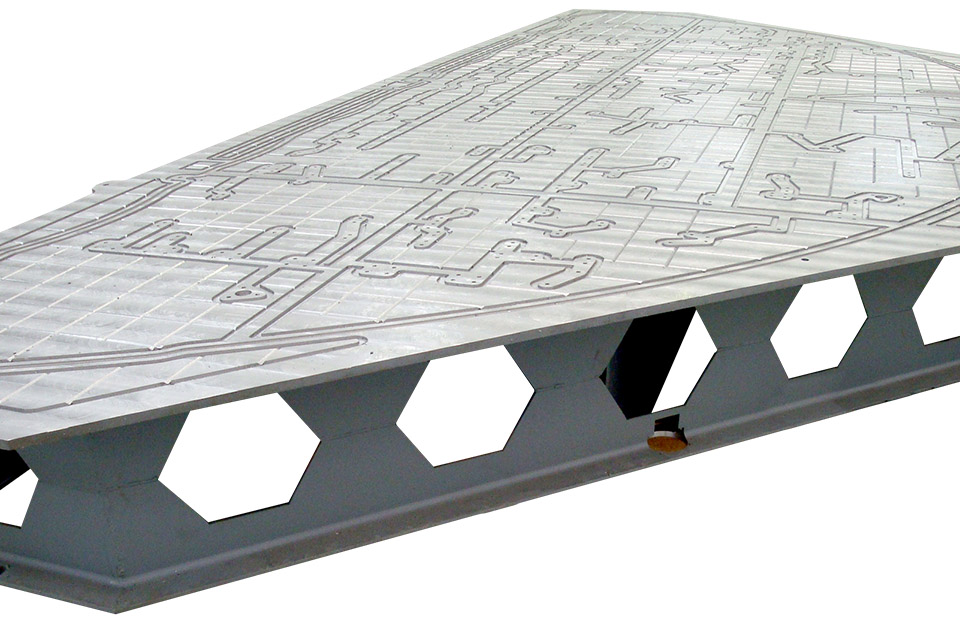

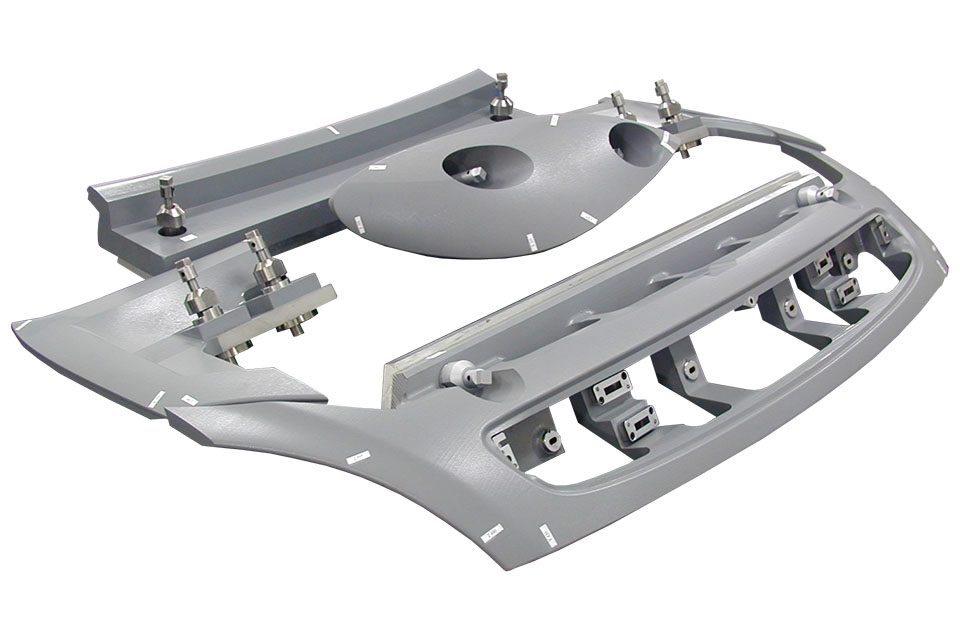

We are experts in the design and manufacture of tools

for composite parts manufacturing for the different productive processes:

Superplastic forming

Hand Lay-up

RTM

Trimming and inspection

ATL

Fiber Placement

Autoclave curing

Hot-Forming

Press-Forming