The goal of the Business Unit Delta Carbon Fiber

Technologies is the manufacture of composite parts,

with out-of-autoclave processes, both impregnation and prepregs

This activity is carried out in our Delta Illescas plant. We have at our disposal an 8,000 m2 workspace with all of the necessary production resources:

Clean room of 1.700 m2 Class 8 (EN ISO 14644-1)

Robotized installation for the manufacture of preforms

Resin injection machine for impregnation processes (DRTM, DLRI)

Cutting machine

Ovens (up to 5000 x 3000 x 2500 mm)

Freezer (5000 x 3900 x 5500 mm)

Machining/milling centers (on five axis up to 24000 x 3500 x 2000 mm)

CNC Software tools (CATIA and TEBIS)

Ultrasonic inspection equipment (US): pulse-echo and phase array

Priming and paint booth

Thanks to the joint work of our R&D and Manufacturing Engineering departments since 2009, four patents have been successfully issued for the development of a new automated manufacturing process for composite preforms

Delta innovative technologies – DRTM (Delta Resin Transfer Moulding) and DLRI (Delta Liquid Resin Infusion)

EFFICIENT PROCESS

AEROSPACE

Developed for the aerospace industry, but applicable to other sectorsHIGH PRODUCTION RATES

CONCEPTS

Their innovative concepts of tools and means allow to reach high production rates100% QUALITY PARTS

QUALITY SYSTEM

Compliance with our customers most demanding requirementsOUTSTANDING RESULTS

DRTM and DRLI

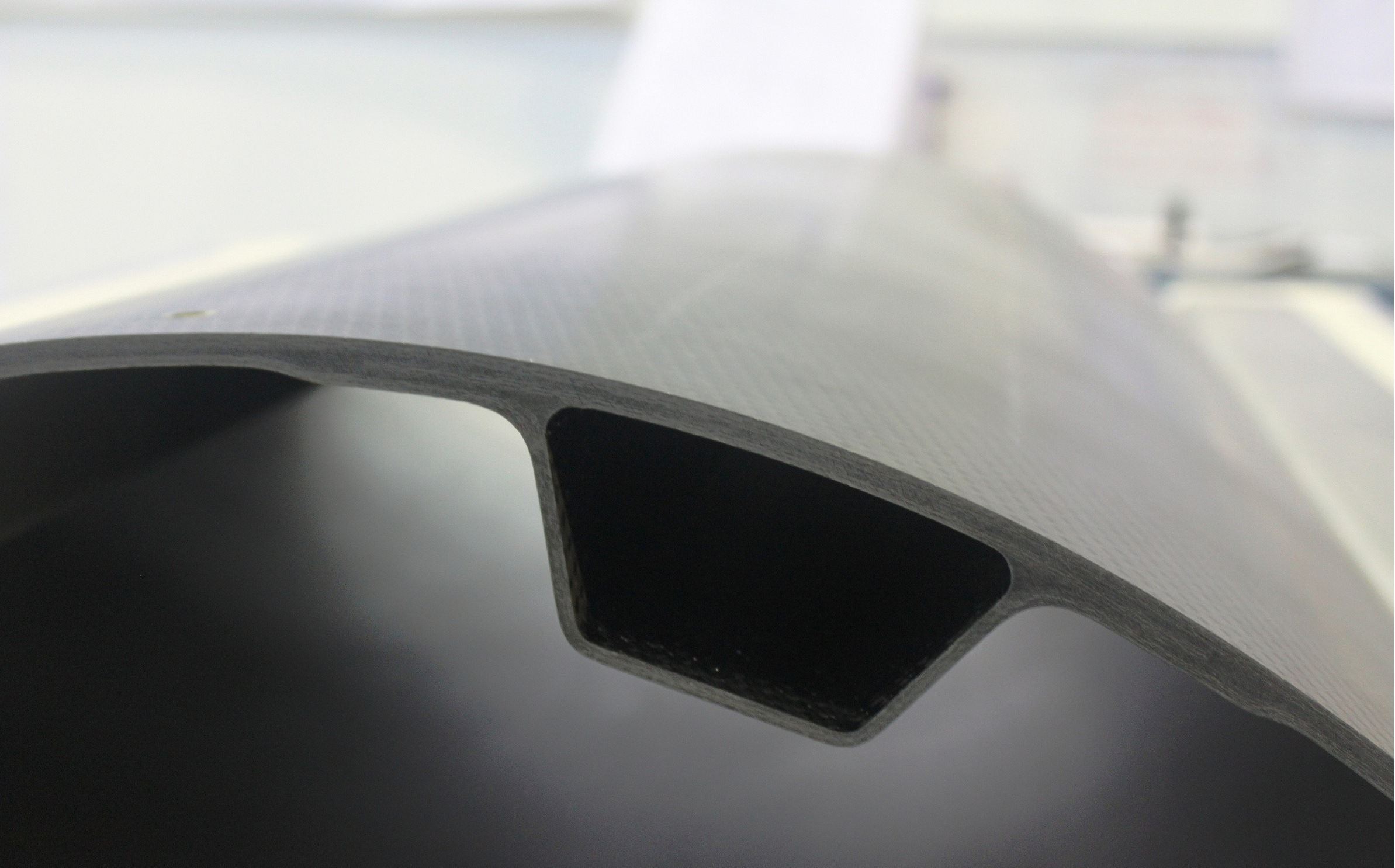

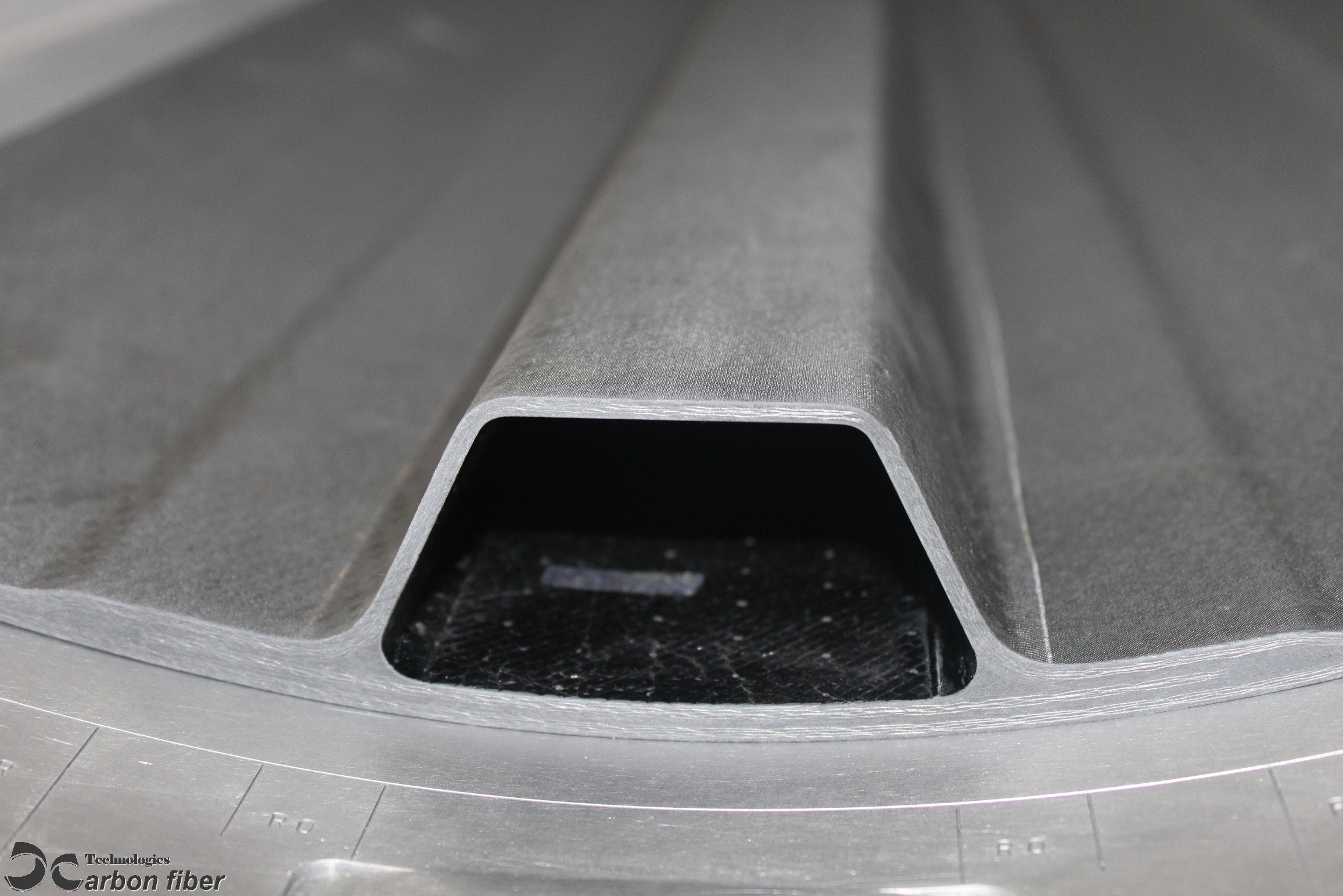

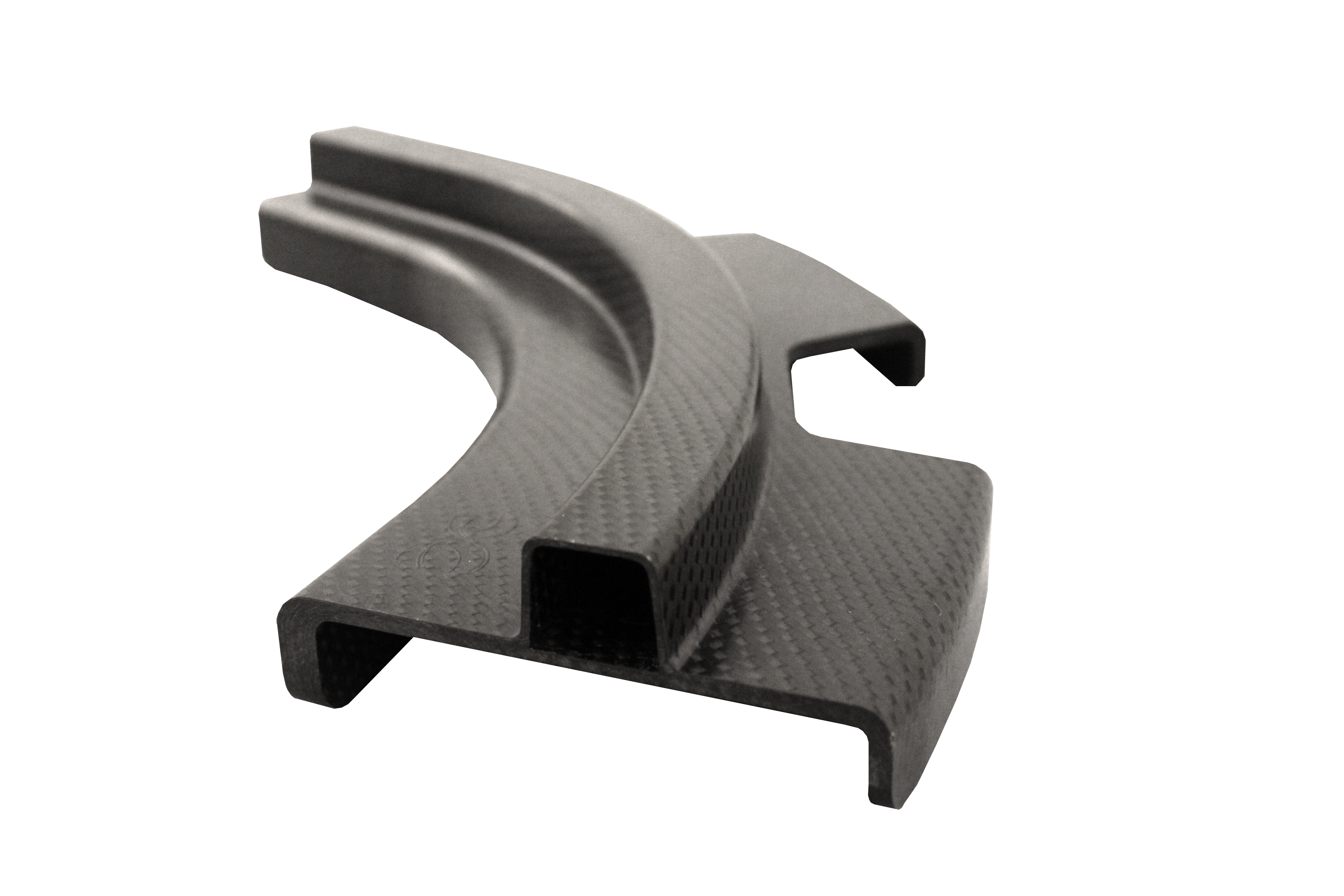

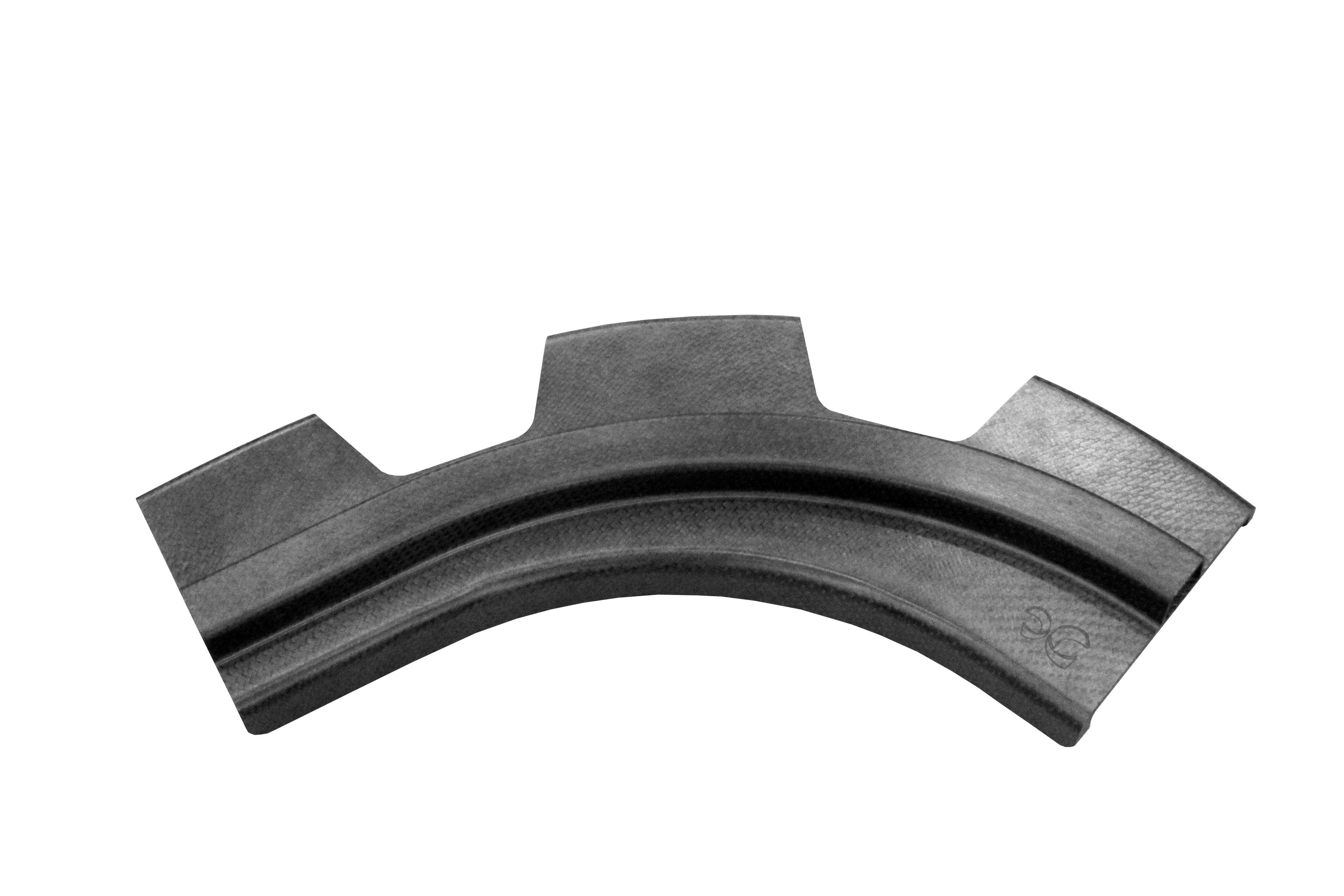

Frames

Fibers orientation optimization

Great reduction of the distortion of fibers: this allows for the fabrication of parts in carbon fiber, which are not currently attainable by means of conventional techniques

Without wrinkles, undulations or impregnation defects

Precision of the tolerances and excellent dimensional repeatability

Flexibility in the configuration of the part, allowing for design and structural weight optimization

Methodology of control and correction of the spring-back

Cost-benefit ratio extensively improved

Reduction of manufacturing lead-times (improvement of the reactivity)

A very significant improvement of production rates compared to conventional processes

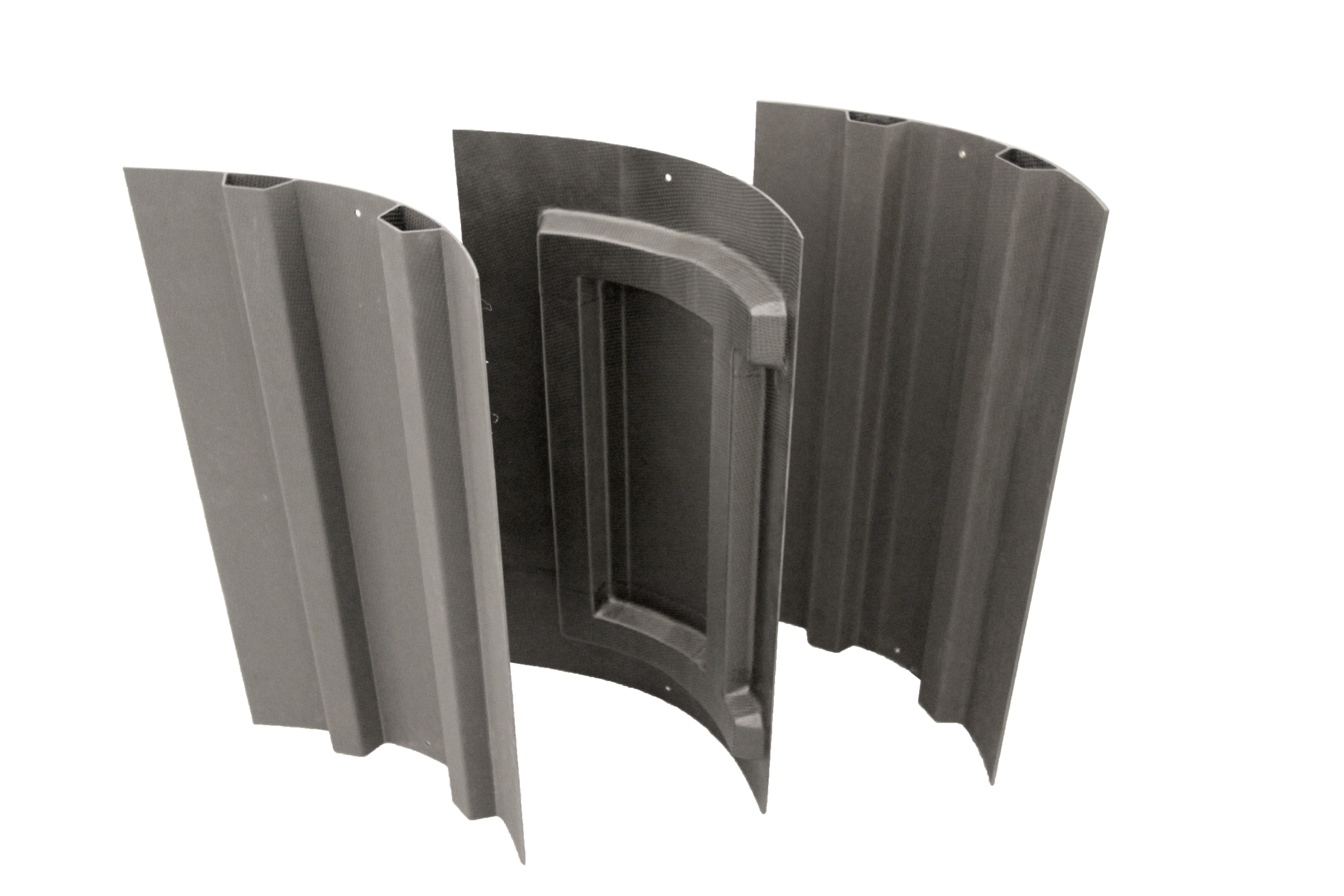

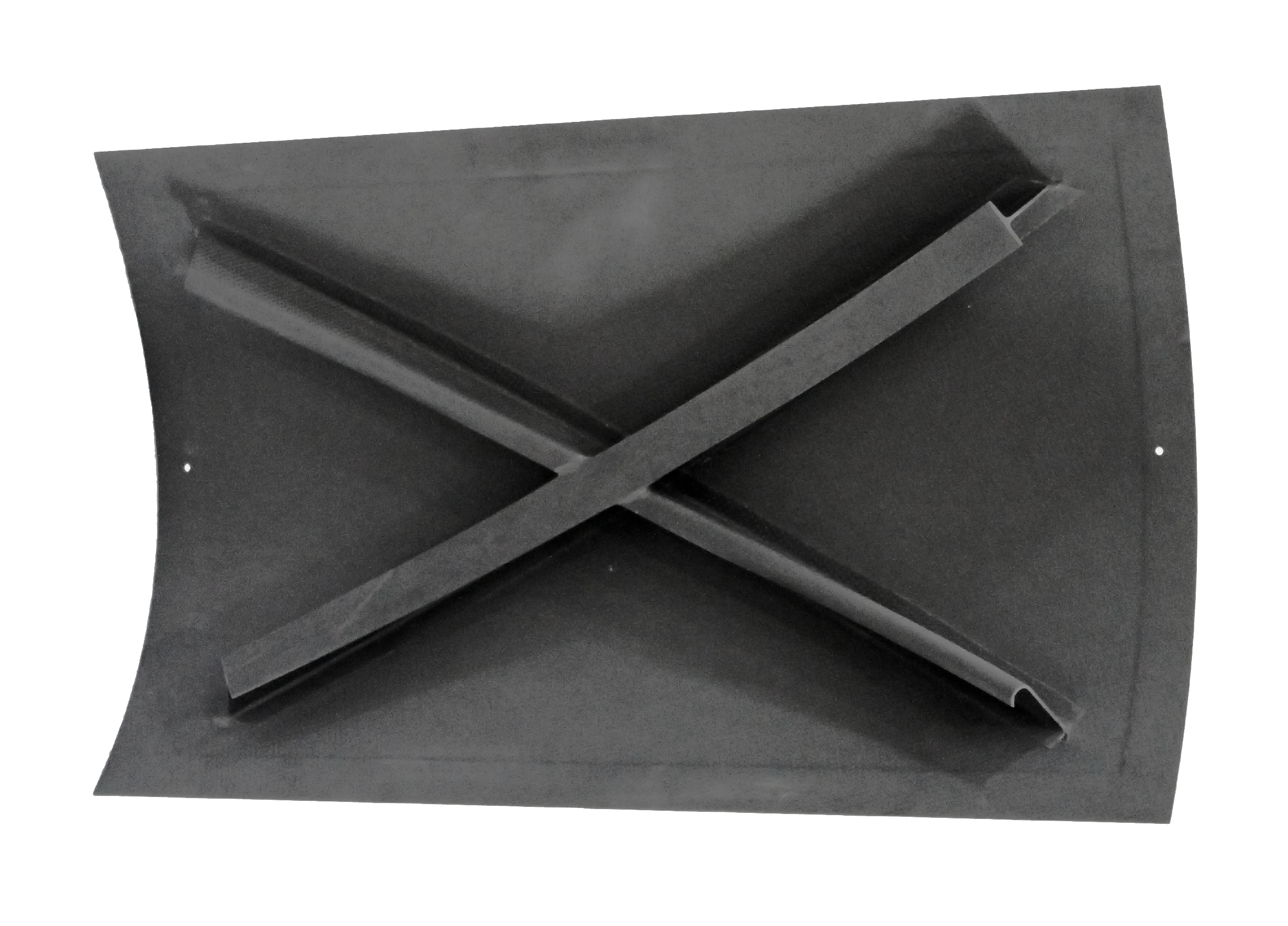

Panels

Applicable to any type of stiffened structure (such as spars, ribs, stringers, fittings and frames)

Double curvature panels with integrated stiffeners and manufactured in one-shoot process

Roving

Homogeneity of the fiber distribution

Fiber volume (58%)

Adaptable to any typical filler geometries