Since 1998 we are present in aeronautical sector,

where we have successfully developed more than 300 turn-key projects,

using for them more than 95% in-house resources

Delta Group has a great history in aeronautics sector and it has gained great experience in its main fields, especially in:

Industrialization of processes

Design and manufacturing of tooling

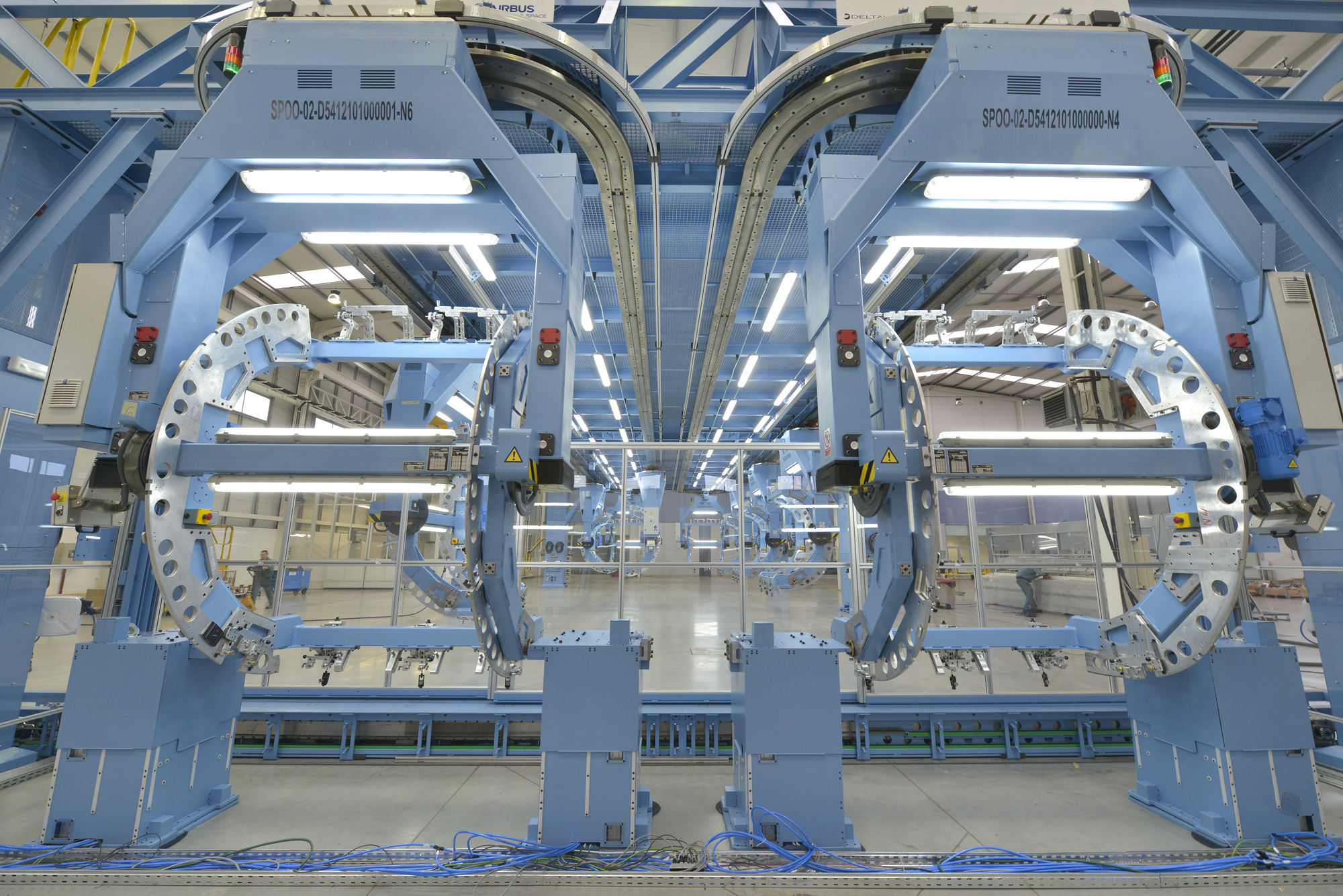

Design and manufacturing of assembly jigs

Industrialization of processes

Design and manufacturing of tooling

Design and manufacturing of assembly jigs

Since the new business unit, Delta Carbon Fiber Technologies, started its operation in 2009, we can add to our fields of knowledge:

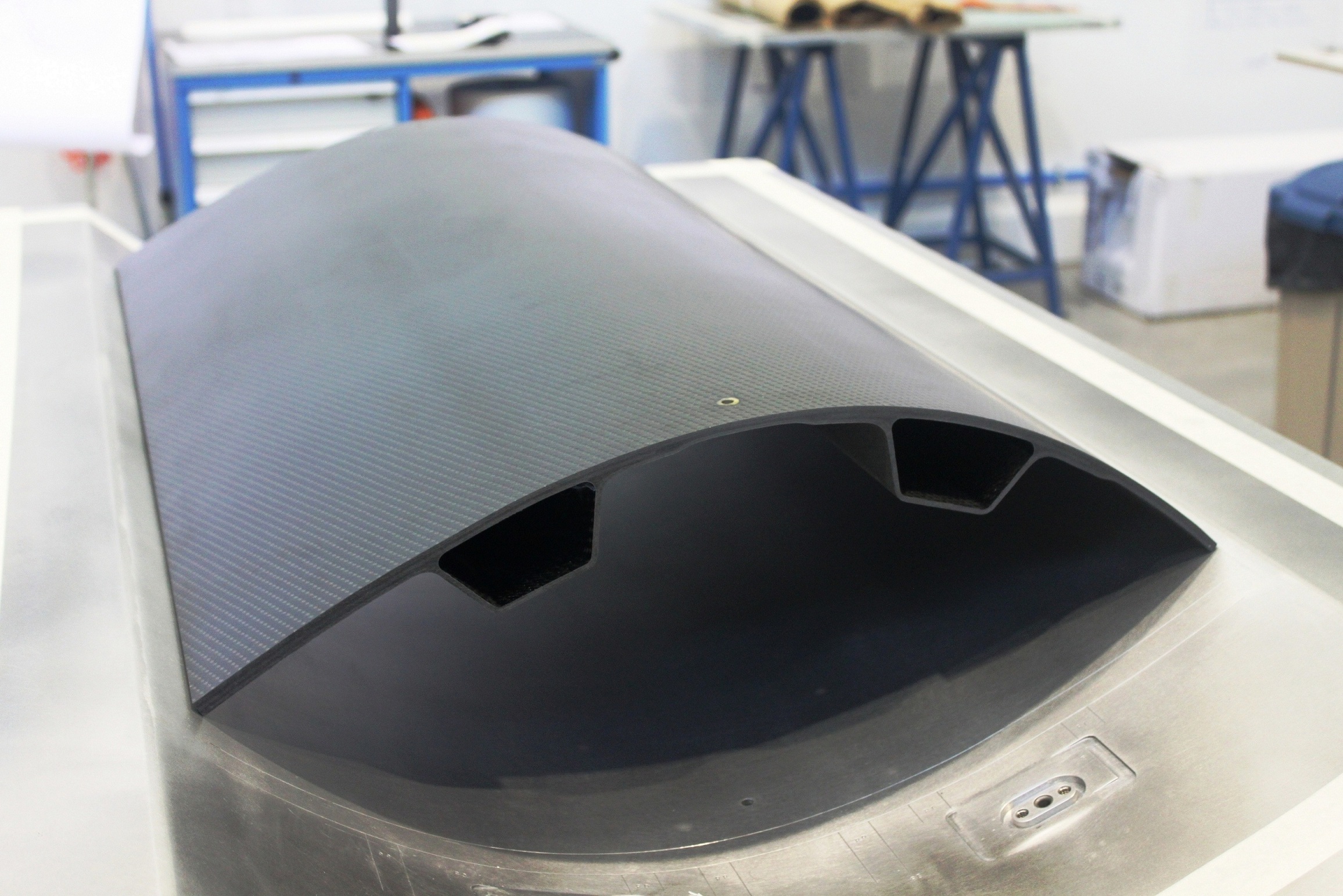

Manufacture of composite parts

Automated/robotised manufacture of composite preforms

Stress and design

These are some of our reference projects

carried out with great success

Industrialization

Manufacturing lines: press-forming of omega S.19 wings

Assembly lines: fan cowl, MRTT, S 19.1

Assembly jigs: rudders 737, S19 A350

Autoclave curing tooling

Milling tooling

RTM tooling

Hot-forming tooling

Components manufacturing

Composites

Frames and stringers (automated processes)

Stiffened panels

Automated roving

Fairings and fittings

Composite tooling

Metals (titanium, aluminium, steel)

Frames

Fittings

Distributors of landing gear

NH90 parts

Final operations

HTP

VTP

Ribs

MLGB traps

Thanks to our vast experience and internal knowledge

DELTA Group has participated in the main

aeronautical programs of the last few years

– A380

– A330/340

– A350 XWB

– A320neo

– V2500

– CRJ-1000

– C-SERIES

– A330-MRTT

– A400M

– P3 Orion

– F18 Maintenance

– B737

– KC-390

– FALCON 7X